Compressed Air Monitoring

Breathing Easy: How Compressed Air Monitoring Enhances Consumer and Product Safety

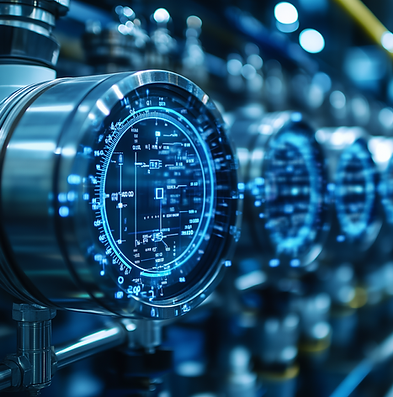

What is Compressed Air Monitoring?

Compressed air is essential in beverage manufacturing, used for various critical applications, including bottling, canning, labeling, and powering pneumatic machinery.

Monitoring compressed air involves continuously assessing the pressure, flow, temperature, and quality of the air in the system to ensure it meets operational and safety standards.

PRODUCTION IMPACT

What are the expected benefits of Compressed Air Monitoring?

30%

decrease in total factory energy consumption

SOURCE: New Food Magazine

20%

reduction in costly CO2 emissions annually

SOURCE: Food Business Insight

25%

decrease in quality-related air contamination issues

SOURCE: New Food Magazine

THE PROBLEM

Hidden Energy Costs of Compressed Air

Compressed air is an essential, multi-use resource in beverage manufacturing that has both indirect and direct contact with food, making it the subject of various consumer safety regulations.

Compressed air that comes in direct contact with food must maintain a strict level of air purity, meaning it is clean, dry, and oil-free.Small, undetectable leaks lead to wasted resources and potential contamination that puts the compliance, quality, and safety of your entire plant at risk.

THE SOLUTION

Trust in a Continuous Monitoring Solution

Pocket Factory’s Compressed Air model continuously monitors all compressed air system data–including consumption, temperature, humidity, dew-point and airflow.

The model detects the presence of unwanted particles in compressed air systems, such as moisture and residual oil, and alerts plant operators to any impurities or changes.

These alerts allow for quick reactions to potential issues, conserving energy usage and preventing downtime and harmful product contamination.

Insights From Innovators

Recommendations and thought leadership on the 4th wave of industry standards and beyond.